Social Landlords > Solid Wall Insulation

Stone properties can either present Hard Plastered or Plaster on Lath internal finishes.

The hard plastered description is used to describe where the wall has been simply plastered straight onto the stone. In such cases - there is no cavity to be utilised

Hard Plastered Solid Walls

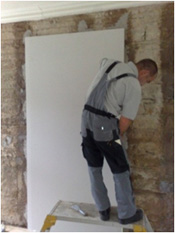

In solid wall construction where the walls are hard plastered ,certain systems can be mechanically fixed straight to the wall and, owing to their very impressive Thermal Conductivity, these can provide target U-Values with the least intrusion into the room. However, these systems are very expensive and can present dust issues where the tenant is not decanted. In cavity wall construction, it possible to mechanically fit a larger range of insulated plasterboards directly to the existing wall.

Where the cost or dust issues prohibit the use of aerogels, high performance foam insulated plasterboards can be used.

Whilst these boards may only be an inch thicker, there may also be a requirement to strap the wall or apply the boards using plaster dabs as shown opposite. This depends on the wall construction (ie: hard plastered solid walls).

Solid Stone Walls

When considering solid stone walling, hard plastered finishes present the same options as the no-fines and solid brick options. However, it is more likely that solid masonry walls will be finished internally with plaster on lath or, if refurbished at some point in the past, plasterboard on timber straps or framing.

Where plaster and lath finishes exist, it is of course cheaper, quicker and less of a mess to over line the walls with a suitable insulated plasterboard. Aboard approximately 60mm thick mechanically fixed through the existing plaster and lath would achieve a target U-Value.

The choice of board and detailing compliments the characteristics of the room and all electric and radiator alterations are carried out by the team.

Internal Insulation of Solid Walls

Advantages |

Provides opportunity for service voids to be created. |

Can allow improvements to be carried out room by room. |

Not impeded by the weather so better suited for compressed programming. |

Generally less expensive especially the higher the building |

No external scaffolding. |

Leads to quick response to heating. |

Good for rooms that are intermittently heated as provides rapid heat response. |

Disadvantages |

Reduces internal room size. |

Incurs cost of new wall finishes and re-decoration new woodwork finishes and services alterations |

Involves the extension or replacement of window cills and skirting. |

Will include temporary removal, extension and reinstatement of radiators, sockets and switches. |

Will affect the operation of the building as rooms/areas are closed off. |

May require the removal of cornice and other ornamental details. |

External Insulation of solid walls

Advantages |

Provides opportunity to improve look of a building. |

The external finish can better protect the building from the elements. |

Does not reduce room sizes in any way |

Little inconvenience internally as work is carried out from outside (only noise). |

Good at eradicating thermal bridging. |

Creates situation with high thermal mass that is ideal for building in continuous occupation. |

Less trades to coordinate and sequence leading to quicker programme – weather permitting. |

External insulation may provide additional structural protection to the building increasing its life and value. |

Disadvantages |

Requires scaffolding. |

More costly than internal measures as insulation has to be protected by render or rain screen. |

Scaffolding can affect traffic and pedestrian routes. |

Incurs cost of rainwater and roof edge alterations. |

May take away from character of the building |

Scaffolding may present privacy issues. |

Requires cill extensions. |

reduce your energy bills

Take action now to reduce your annual energy costs. The results can be striking.

our green credentials

We've always recognised the need to be responsible with our use of energy and resources.